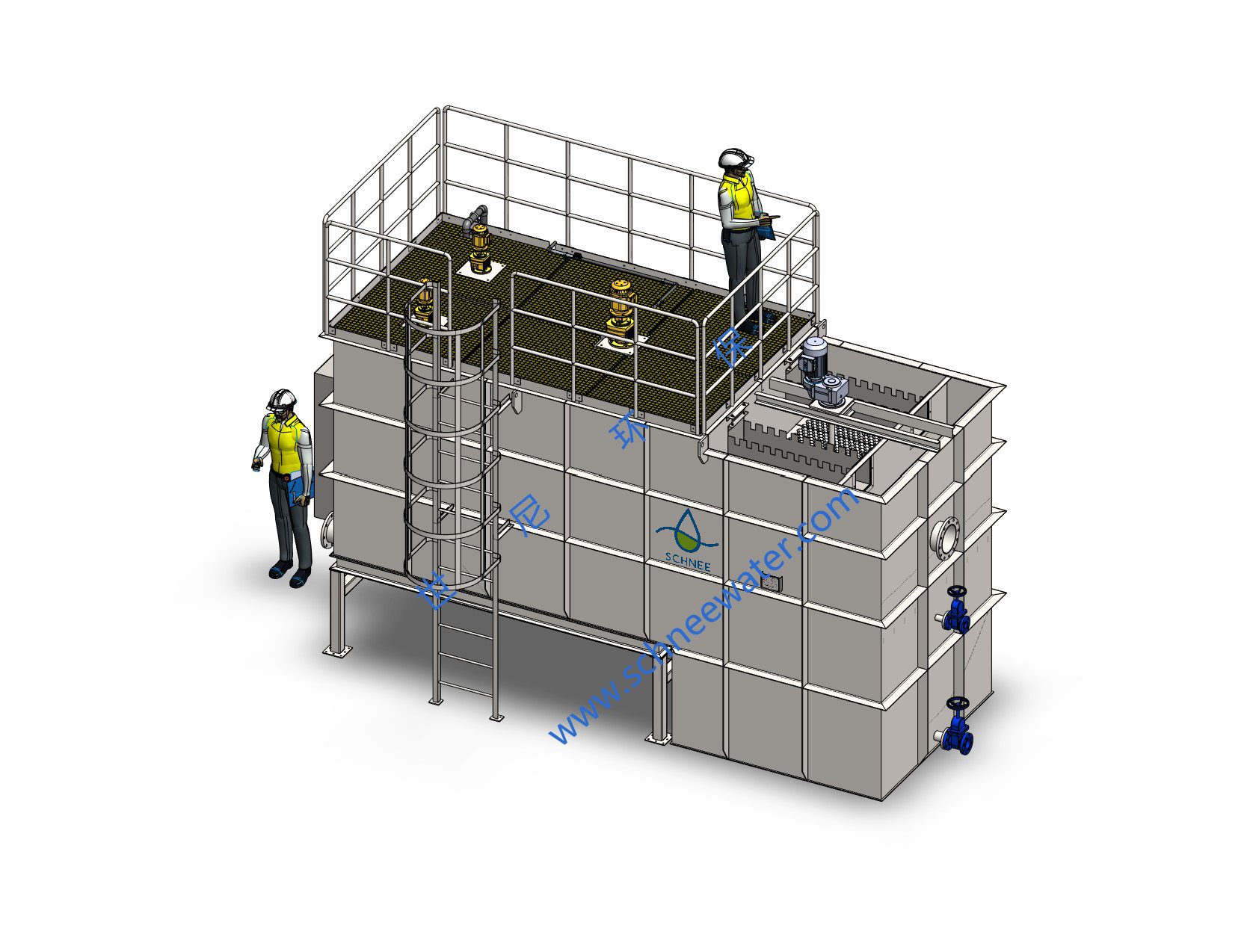

MBBR PACKAGE

Moving Bed Biofilm Reactor (MBBR) Technology

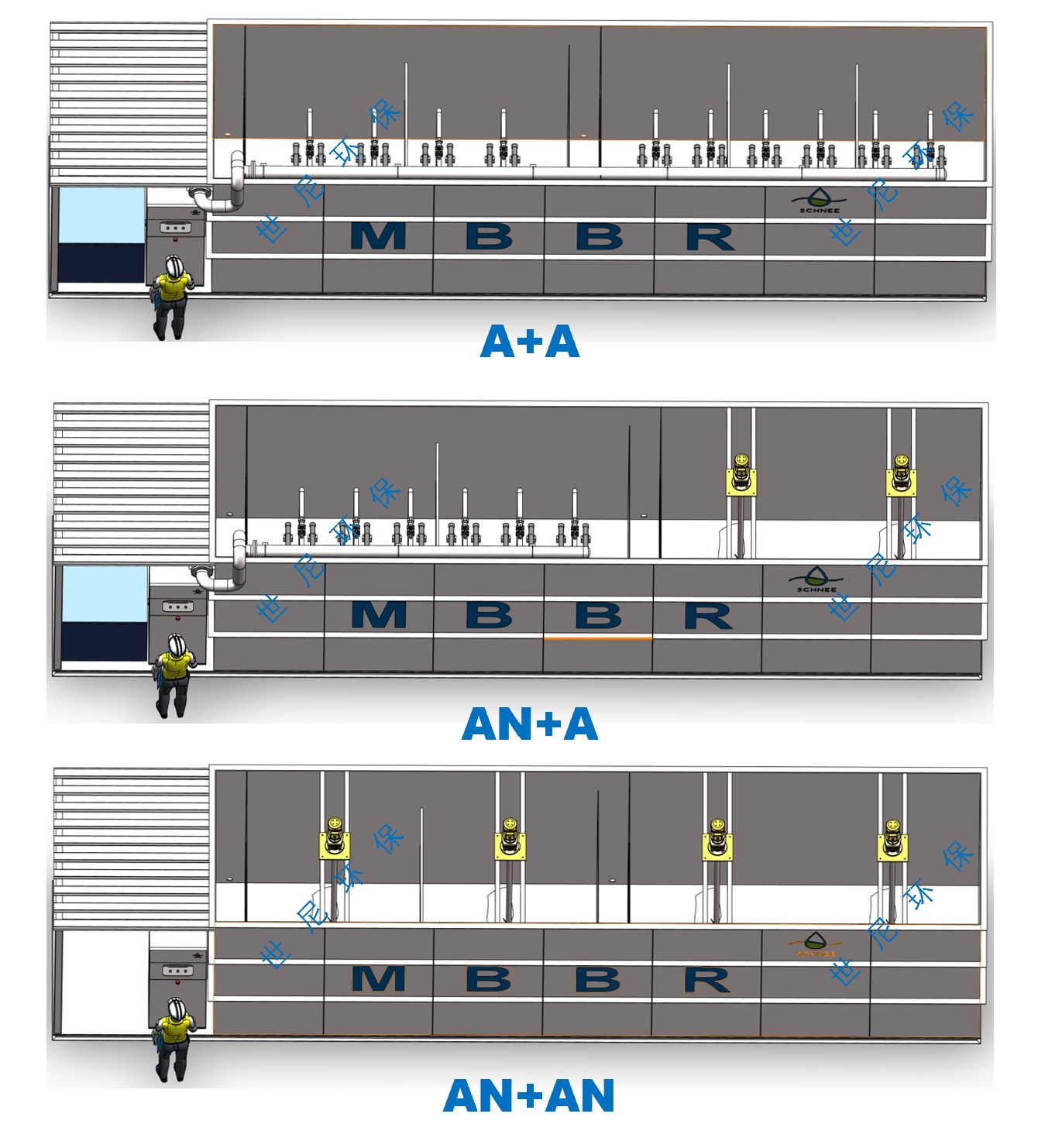

MBBR combines the advantages of biofilm processes (high sludge concentration, long sludge age, no sludge reflux) and activated sludge processes (non-clogging design, uniform water distribution, and mixing). It is versatile, suitable for organic matter removal, nitrogen/phosphorus removal, new wastewater plants, and retrofitting existing facilities.

MBBR Process Features

-High efficiency, compact design: Doubles/triples treatment capacity in upgrades without expanding footprint.

-Robust performance: Resists shock loads, temperature fluctuations, and toxic substances better than activated sludge.

-Low maintenance: Non-clogging aeration, durable mixing systems, and optimized biofilm carriers.

-No clogging, full tank utilization: Agitated carriers prevent dead zones, ensuring complete tank usage.

-Flexible integration: Compatible with any tank shape/size and existing activated sludge systems.

-Long lifespan: High-quality HDPE carriers, aeration systems, and components ensure 20+ years of service.

SCHNEE MBBR Technology Advantages

Tank design: Optimized water distribution/outlet systems minimize shock loads and carrier accumulation.

Hydrophilic carriers: Surface-treated HDPE carriers enhance biofilm formation.

Efficient aeration: Uniform bubble distribution, 20-year lifespan, low maintenance.

Carrier retention: Custom screens prevent loss, wear, and buildup.

Defoaming: Airlift-based system, zero water consumption, covers 4m per unit.

Specialized mixing: Anaerobic/anoxic mixers protect carriers while ensuring performance.

Product